Uncover 10 important focus areas for startups and MSMEs in product improvement, from structure to innovation, and navigate the trail to success within the dynamic manufacturing panorama.

Within the dynamic panorama of recent manufacturing, the journey from a design idea to a tangible product is intricate and interesting. This text is meant to supply precious insights and steerage for startups and Micro, Small, and Medium Enterprises (MSMEs) specialising in electronics and electromechanical product improvement. It highlights ten important focus areas that may considerably improve the effectivity and effectiveness of product improvement processes. These key areas are meticulously explored to help these enterprises in navigating the intricate realm of product improvement, finally aiming to foster innovation and success on this dynamic trade.

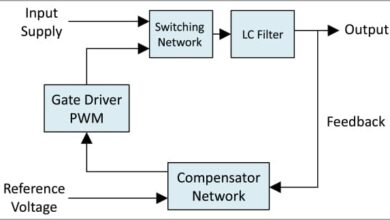

Sturdy Basis in Product Structure

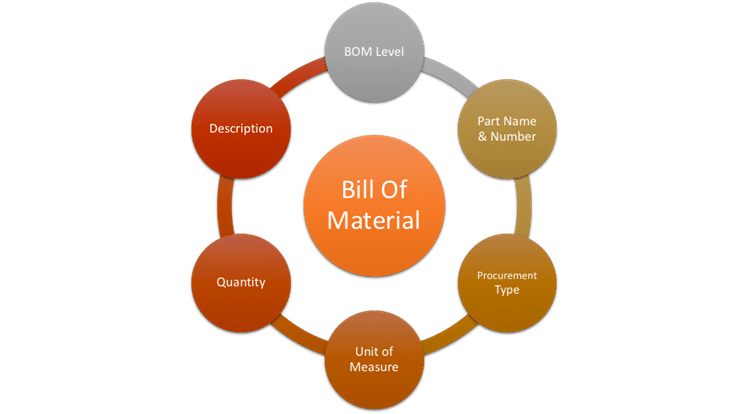

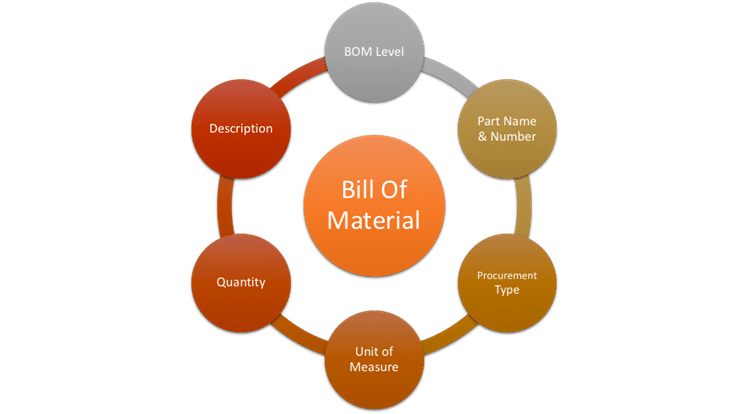

The preliminary section of product improvement revolves round creating a sturdy product structure. A well-defined invoice of supplies (BOM) detailing half numbers, producers’ names, and element rankings is essential. This course of is just not unique to massive organisations; even startups ought to diligently categorise their BOM, laying a stable groundwork for future development.

In product improvement, remodeling an concept right into a prototype is complicated, stuffed with uncertainties and potential communication points. Contemplating manufacturing preferences and packaging wants, addressing design imperfections and lack of shopper suggestions early on is essential. Establishing an in depth database is crucial, as a product’s parts can develop from just a few to hundreds, highlighting the necessity for organisation and proactive planning. This contains understanding roles and sustaining a complete database. Procuring Class B and C parts, like energy provides and plastic components, requires anticipating lead instances and choosing the proper expertise platforms. A well-organized design course of and schedule streamline the event cycle, improve effectivity, and help innovation, making product launches simpler.

Course of Implementation and Development Technique

Implementing well-structured processes is important for any organisation, no matter measurement. As corporations evolve, these processes can speed up development, guaranteeing the organisation stays aggressive and adheres to international requirements.

Addressing Design Challenges and Options

Designers typically encounter challenges guaranteeing that each facet of the product, from structure to closing design, is flawless. Efficient communication and complete info gathering are key to avoiding iterative interactions and reaching a finalised BOM. This strategy streamlines the design course of and fortifies the connection between designers and producers.

Emphasis on Database and Element Administration

Sustaining an organised database is crucial for merchandise with as few as ten parts. Because the product vary expands, this database will turn into invaluable for managing an more and more complicated array of components.

Understanding Element Classification

Differentiating between varied element courses, resembling energy provide components and plastic components, is crucial. This information aids in planning and addressing lead instances early within the design section, finally contributing to a extra environment friendly improvement course of.

Efficient Scheduling and Platform Choice

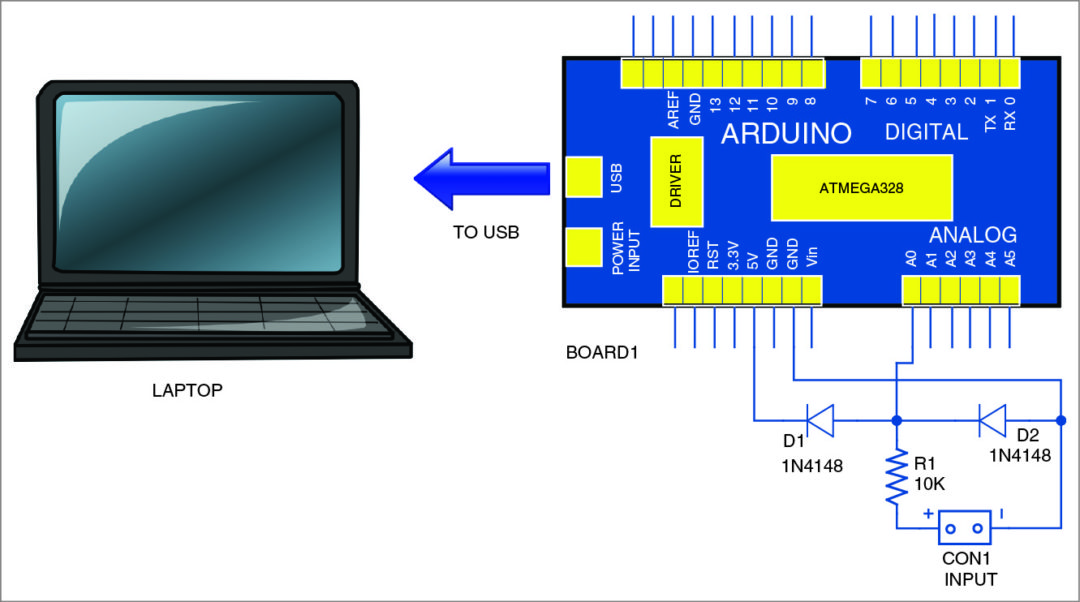

Choosing the proper microcontroller, microprocessor, or FPGA platform needs to be made early within the design course of. This foresight permits for higher scheduling and undertaking planning, minimizing delays and optimizing useful resource allocation.

Fostering Innovation and Adaptability

Innovation isn’t just about creating new merchandise; it’s additionally about adapting and enhancing present processes and designs. Encouraging a tradition of innovation throughout the group results in higher merchandise and extra environment friendly manufacturing processes.

Collaboration and Communication

Communication between all stakeholders, together with designers, producers, and purchasers, is essential. Common interactions and clear communication channels can considerably scale back misunderstandings and guarantee everyone seems to be aligned with the undertaking’s targets.

High quality Management and Requirements Compliance

Adhering to high quality management measures and international requirements is non-negotiable. This dedication enhances the product’s marketability and builds belief and credibility with purchasers and end-users.

Steady Studying and Ability Growth

The technological panorama is ever-evolving, and staying up to date with the newest traits and abilities is important. Fixed studying and improvement be certain that the organisation stays on the forefront of innovation.

For startups and MSMEs venturing into electronics and electromechanical product improvement, embracing these rules can pave the best way for fulfillment and sustainability in a aggressive market. As we proceed to evolve, our dedication to innovation, high quality, and excellence stays unwavering, inspiring others to embark on their journey of development and discovery.

The Significance of Element Packaging in PCB Design

Within the ever-evolving world of Printed Circuit Board (PCB) manufacturing, choosing applicable element packages is pivotal within the design and manufacturing. This selection turns into notably essential for startups and small corporations who may not have entry to classy laboratories and gear. Bigger element packages, as an example, will be extra manageable for in-house changes and reworks, streamlining the preliminary design phases.

As corporations progress from the Proof of Idea (POC) phases to mass manufacturing, understanding the implications of various packaging varieties turns into important. This information needs to be mirrored within the Invoice of Supplies (BOM), guiding Digital Manufacturing Providers (EMS) companions in choosing essentially the most environment friendly packaging for high-volume manufacturing. For instance, reel-type packages improve the pace of SMT machines in element placement, whereas tray and tube packages can decelerate the position course of.

Completely different purposes, resembling energy, protection, or aerospace, impose particular necessities on element packaging. In demanding environments, resembling area purposes, parts like Ball Grid Arrays (BGAs) and smaller footprints are sometimes prevented attributable to issues like vibration failures. Thus, understanding and adhering to those environmental and application-specific issues is important in designing dependable and sturdy electronics.

Even in the present day, many designers rush into manufacturing with out adhering to requirements or processes, resulting in quite a few points post-manufacturing. The significance of standardising schematic symbols and PCB footprints can’t be overstated. Adherence to requirements resembling IPC 7351 ensures that parts are appropriately positioned on the grid, stopping connection points and enhancing the design’s manufacturability. The design of SMT parts should comply with particular tips, considerably when scaling manufacturing from prototypes to bigger volumes. A typical misunderstanding between designers and producers typically arises attributable to design scalability and manufacturability discrepancies. Utilising footprint requirements ensures that as manufacturing scales, the design stays possible for manufacturing, avoiding potential conflicts and high quality points.

Incorporating 3D fashions of parts in PCB design is more and more essential, particularly in designs with tight enclosures or particular spatial necessities. These fashions enable for preemptive changes in element choice and placement, addressing potential points earlier than finalising the PCB design and continuing with mechanical CAD outputs.

Efficient Element Placement Methods

Efficient placement of parts on a PCB is essential for optimum performance and reliability. Designers should plan the position contemplating inputs and outputs, mechanical stability, connector varieties, and sign integrity. Segregating totally different useful blocks (e.g., energy provide, sign processing, Analog and RF sections) and contemplating thermal administration within the placement technique are key elements in reaching a profitable PCB design.

Thermal administration is important to PCB design, notably for parts that generate important warmth. Making certain enough pure airflow, utilizing applicable warmth dissipation strategies, and avoiding clustering important parts close to heat-generating areas are important practices. These issues not solely affect the efficiency of the PCB but in addition affect the effectivity of SMT operations throughout manufacturing.

For startups and rising corporations within the electronics sector, understanding and implementing enough element packaging and placement methods are important steps in the direction of environment friendly and dependable manufacturing. Adhering to trade requirements, contemplating application-specific necessities, and planning for scalability and thermal administration are key parts of a profitable electronics manufacturing course of. As corporations develop and evolve, these practices will lay a robust basis for product improvement, guaranteeing that their designs are modern and manufacturable at scale.

Transitioning from a profitable prototype to mass manufacturing is a fancy but important step for any electronics producer. This journey includes not solely proving the idea and performance of a product but in addition scaling up manufacturing effectively and cost-effectively. There are a number of key elements producers should think about to navigate this transition easily. They’re talked about as follows:

Embracing the Design for Excellence (DfX) Strategy

DfX, encompassing Design for Manufacturing (DFM), Design for Meeting (DFA), and Design for Check (DFT), is essential in scaling manufacturing. DFM ensures that PCB designs adjust to manufacturing capabilities, together with footprint accuracy, hint width spacing, and drill sizes. DFA considers meeting elements, like thermal dissipation and element placement, to forestall soldering points throughout reflow. DFT includes planning for environment friendly testing methods, whether or not guide or automated, to ensure product reliability at scale.

Element Choice and Lead Time Administration

Deciding on the appropriate parts on the outset is important. This course of contains contemplating lead instances and guaranteeing element availability throughout scale-up. Keep away from reliance on open-source codes which may not be suitable with the design and be certain that the code aligns with the {hardware}.

Significance of Having Alternate Sources

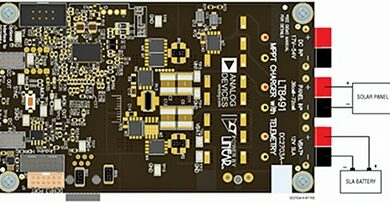

The semiconductor scarcity in 2020 highlighted the necessity for alternate sources and mixed footprints in element choice. This foresight permits for flexibility in manufacturing and well timed market supply, particularly for important parts like microcontrollers, reminiscence, and microprocessors.

Growing an Efficient Check Technique for PCB and Programs

A sturdy take a look at technique, notably for methods comprising a number of PCBs, is crucial. This technique ought to embody particular person PCB and system integration testing, contemplating elements like mechanical connectors and guaranteeing open I/Os for future performance testing.

Adhering to International Requirements

Understanding and complying with international requirements is paramount. This compliance varies throughout industries, resembling automotive or aerospace, the place particular element requirements have to be met to make sure product reliability and market acceptance.

Deciding on the Proper Manufacturing Companion

Selecting an applicable Digital Manufacturing Service (EMS) companion is important. Producers should align with companions able to dealing with their particular necessities, whether or not coping with distinctive supplies like Rogers for RF purposes or managing totally different temperature profiles throughout meeting.

Element Engineering and Obsolescence Administration

Efficient element engineering includes steady price discount efforts and exploring alternate half numbers. Obsolescence administration is one other important facet, guaranteeing that parts stay accessible all through the product’s lifecycle.

Homologation for Worldwide Markets

Adapting merchandise for various markets is important. This adaptation accommodates varied electrical requirements, resembling voltage variations between the US and European areas. Homologation ensures that merchandise meet particular nation or regional requirements for market entry.

Scaling from a Proof of Idea (POC) to mass manufacturing in electronics manufacturing is an artwork that includes meticulous planning, detailed course of adherence, and strategic decision-making. Every stage, from element choice to closing meeting and testing, performs a pivotal function in guaranteeing the profitable transition of a product from prototype to high-volume manufacturing. By following these tips, producers can navigate the complexities of this journey, guaranteeing product reliability, cost-effectiveness, and market competitiveness. This complete strategy enhances the product’s lifecycle and solidifies the producer’s popularity within the dynamic world of electronics.

This text is from a tech discuss session at Delhi EXPO 2023, Delhi, by Prabu Murugan, Co-Founder & Director. ZettaOne Applied sciences. Transcribed and curated by Akanksha Sondhi Gaur, Senior Technical Journalist at EFY.