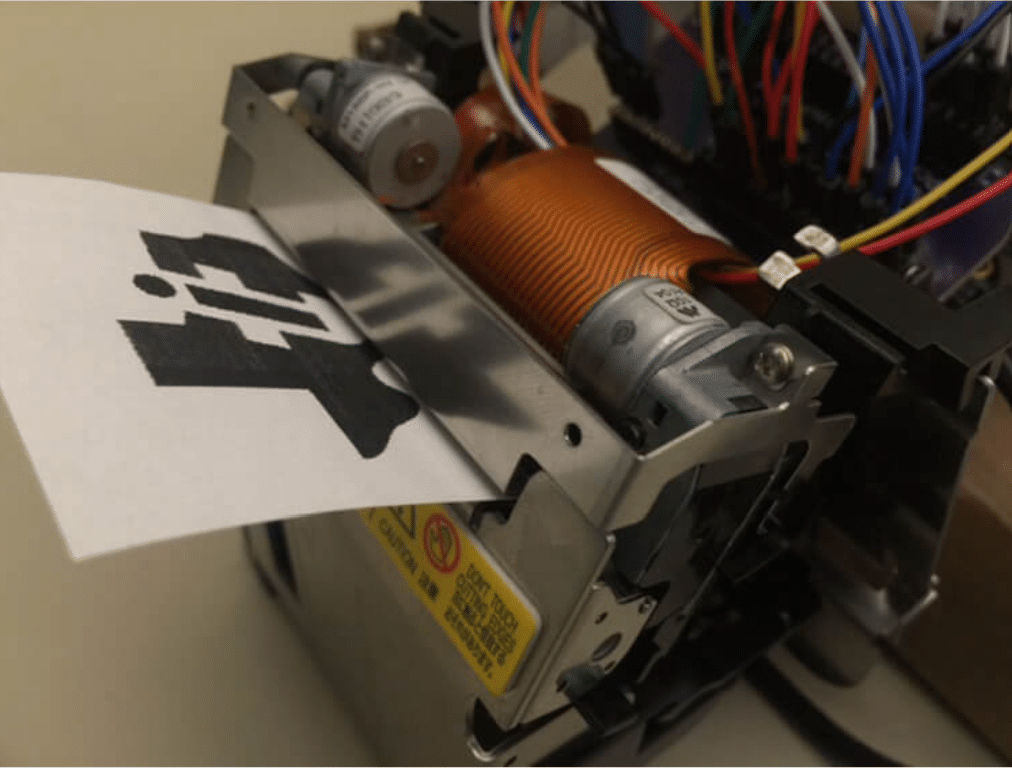

The design helps management thermal printers successfully, making certain correct printing even when the working system is unpredictable.

Thermal printing is a vital expertise extensively used throughout numerous industries as a result of it produces high-quality prints rapidly and effectively. Famend for its pace, thermal printers considerably outpace conventional inkjet or laser printers, making them ultimate for fast-paced environments similar to retail and meals providers. They’re cost-effective, relying solely on thermal paper or labels, eliminating the necessity for costly ink or toner. These printers’ reliability and low upkeep additional improve their enchantment, as they function with fewer consumables and mechanical elements, lowering the probability of downtime as a consequence of malfunctions. The Programmable Realtime Unit – Industrial Communications Subsystem (PRU-ICSS) of the AM335x SoC facilitates realtime, deterministic GPIO management, functioning successfully even below a non-deterministic working system. The reference design from Texas Devices (TI) illustrates a selected software of the PRU-ICSS in immediately managing a thermal printer module.

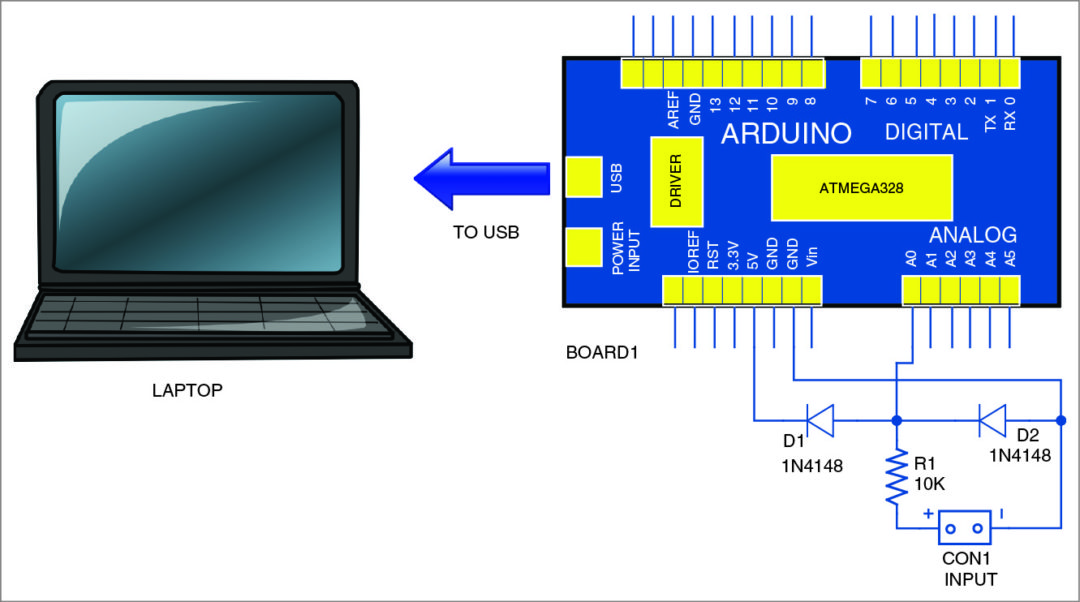

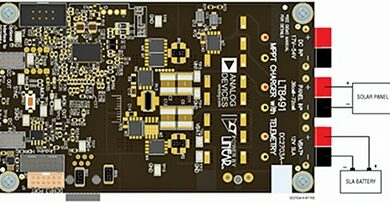

This design highlights a thermal printer software that makes use of the twin Programmable Realtime Unit and Industrial Communication Subsystem (PRU-ICSS), particularly the Sitara AM335x processor from Texas Devices. In contrast to typical thermal printing modules, which characteristic a controller board that includes a microcontroller to deal with the printer’s mechanisms and interface with an software processor by serial or parallel connections, this design employs the PRU-ICSS to handle all management capabilities. This removes the necessity for a separate printer controller board to streamline the system structure.

The principle parts of the thermal printer on this setup embody stepper motors, which advance and minimize the paper, and a semiconductor-based thermal printing component that creates photos line-by-line on thermally delicate paper. By integrating these capabilities inside the PRU-ICSS, the design reduces parts’ redundancy and enhances operational effectivity, making certain high-quality print outputs.

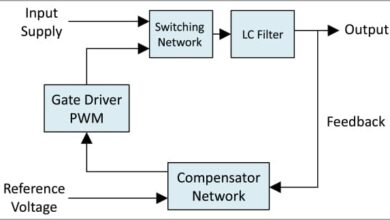

The thermal printer calls for exact enter waveforms to successfully management the stepper motors and print head. Such agile management is difficult to realize on a superscalar CPU structure when working below a high-level working system, because it can not assure the timing of inputs and outputs, resulting in substandard print high quality. In distinction, the PRU-ICSS excels at producing correct real-time, deterministic management alerts and waveforms. This functionality stems from the PRU’s specialised structure and its independence from the ARM host processor, enabling it to handle timing-critical duties successfully.

The PRU-ICSS options two unbiased 32-bit RISC cores, every working at 200 MHz. These cores are constructed on a single-cycle structure, making certain deterministic execution. Moreover, every PRU core has its personal 8-KB Knowledge RAM and shares entry to 12 KB of Shared Knowledge RAM.

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has further information concerning the reference design. To learn extra about this reference design, click on right here.