The design includes a multi-axis servo drive system utilizing a quick serial interface for enhanced communication appropriate for industrial automation and robotics.

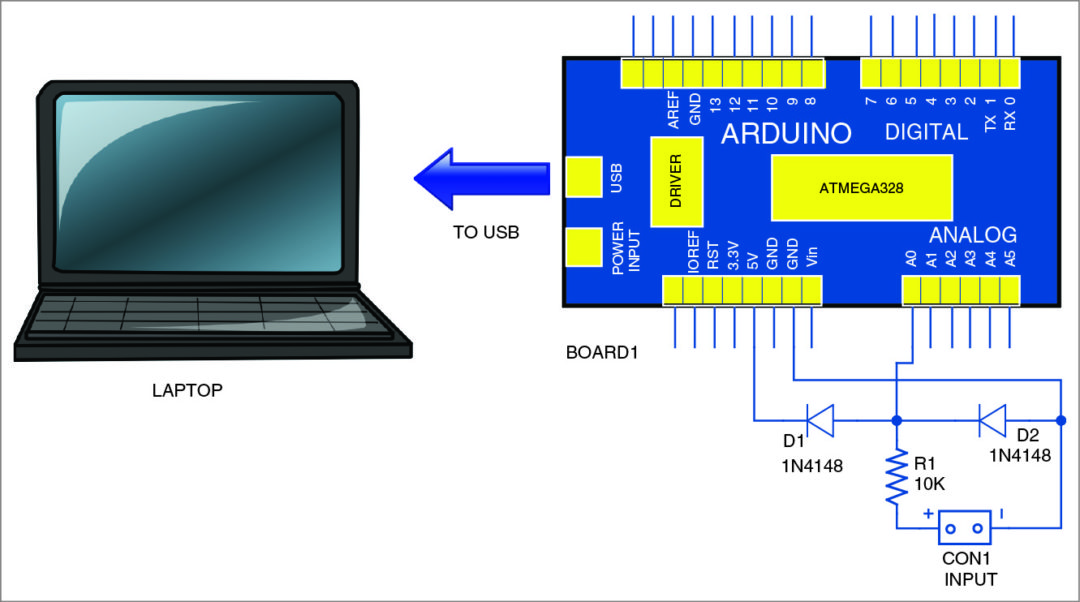

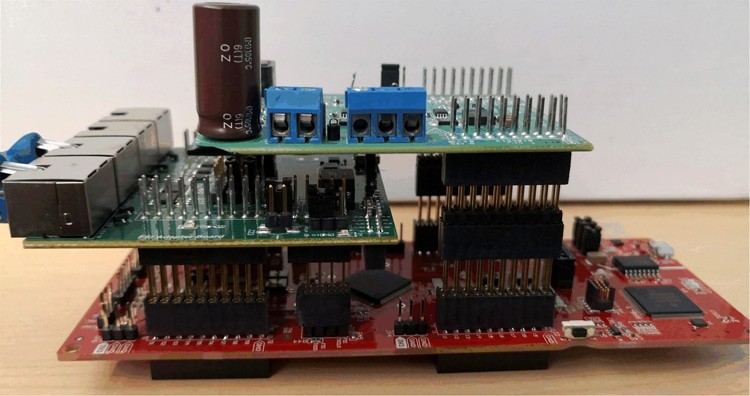

Movement management is essential in quite a few industrial functions, notably multi-axis movement management programs, comparable to manufacturing unit automation and robotics. The analysis of those multi-axis programs usually focuses on a number of key features: management efficiency, connectivity, ease of use, and price. Trendy multi-axis programs demand excessive decision and bandwidth inside every motor controller and fast communication between the grasp and slave models. Whereas servo inverters in these programs are generally related by way of Ethernet-based discipline bus programs and managed by a main controller, Ethernet introduces excessive prices and complexity. The reference design from Texas Devices (TI) illustrates a distributed multi-axis servo drive system using a Quick Serial Interface (FSI) managed by C2000 real-time controllers.

The multi-axis servo drives are essential in numerous sectors, together with manufacturing unit automation and robotics, the place price per axis, efficiency, and user-friendliness are pivotal. FSI presents a cheap and reliable high-speed communication resolution with minimal jitter, able to linking a number of C2000 models in a daisy-chain configuration. Every F28004x system features as a real-time controller for a subordinate axis, managing the motor present management loop on this setup.

Industrial motor drives, manufacturing unit automation, and management programs are utilized in numerous industrial settings. AC drive management modules play a vital function in managing and optimizing these functions’ efficiency, making certain environment friendly operation and integration into broader automation options.

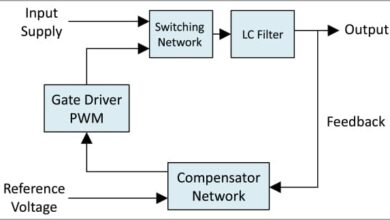

The system’s options reveal superior capabilities in high-speed communication, using a quick serial interface (FSI) for real-time transmission of pace, place, and present command knowledge throughout a number of units. This setup facilitates efficient system coordination, making certain swift and dependable knowledge dealing with. The system additionally implements place and velocity management loops for all slave axes managed by an F2838x-based grasp node, and a torque/present loop on every F28004x-based slave node, enhancing management precision.

A single F2838x unit can management as much as 16 axes, with functionalities enabling simultaneous begin and cease of every axis. This integration achieves excessive bandwidth and exact management of a distributed multi-axis motor drive system, making it superb for advanced industrial functions. The multi-core performance of the F2838x is utilized to implement pace and place management, in addition to knowledge alternate with all slave nodes over FSI, whereas additionally managing primary axis motor management and EtherCAT communication with PCs.

Moreover, the system consists of an built-in SFRA device on F28004x and F2838x platforms to help on-line tuning of pace and present loops, making certain optimum efficiency. The event course of incorporates incremental system builds, permitting for the verification of various software program modules step-by-step to make sure reliability and performance at every stage of integration.

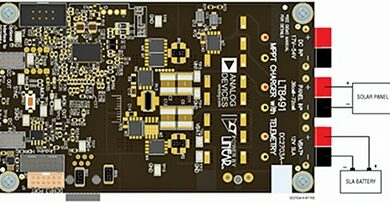

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has further knowledge concerning the reference design. To learn extra about this reference design, click on right here.