Designed to face up to dust, moisture, and oil, this resolution eliminates wear-prone elements and avoids magnet reliance, enhancing longevity in automotive, equipment, and client electronics purposes.

In conventional rotary management knob designs, mechanical contact-based programs have been generally used, notably within the Opara system. Nonetheless, these mechanical programs typically endure from reliability points resulting from put on and tear on transferring elements, resulting in pricey replacements over time. Equally, optical sensing alternate options, whereas contactless, are additionally susceptible to environmental elements like dust and dirt, which influence their reliability in varied automotive and industrial purposes.

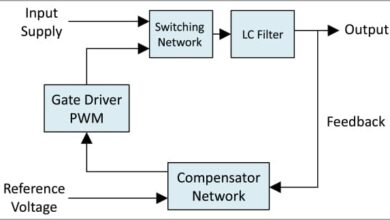

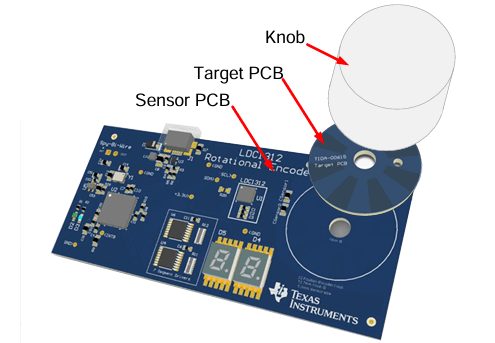

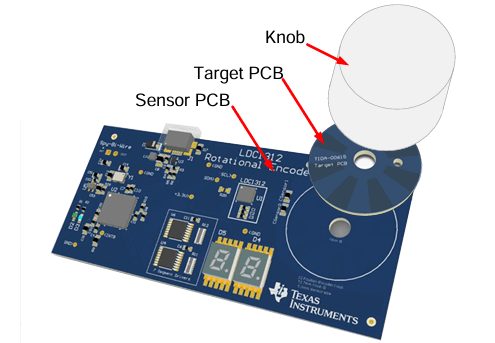

An modern strategy to handle these limitations is an inductive sensing-based incremental encoder design. This design TIDA-00615 by Texas Devices (TI) affords a contactless, sturdy, and cost-effective interface for management inputs. By leveraging inductive sensing know-how, this resolution capabilities successfully even in harsh environments the place dust, moisture, or oil may impede different sensing mechanisms. Notably, this design doesn’t depend on magnets, additional enhancing its sturdiness and applicability throughout varied sectors.

The inductive sensing-based rotary knob makes use of low-drift capacitive (LDC) know-how to allow high-reliability place monitoring with out the necessity for recalibration. It operates inside a 2.7V to three.6V energy vary and consumes lower than 3.5 mA of energy (excluding energy wanted for the microcontroller and LED indicators). A particular characteristic is its flexibility, permitting the sensor and knob to be positioned remotely relative to the LDC1312/4 gadget. The design helps as much as 32 steps per rotation and might be adjusted to accommodate multiples of 4 positions, providing versatility for varied management purposes. Moreover, it’s able to measuring rotations exceeding 1000 RPM with minimal computational necessities, needing solely 40 bytes of RAM, 800 bytes of ROM/Flash, and 0.1 MIPS for a 5 ms response fee.

This rotary management knob design is well-suited for a number of purposes, together with infotainment programs in automotive settings, equipment interfaces (resembling cooktops and cleansing units), and residential audio or client electronics programs. It additionally works successfully as a rolling jog wheel, making it a versatile choice for varied system management interfaces.

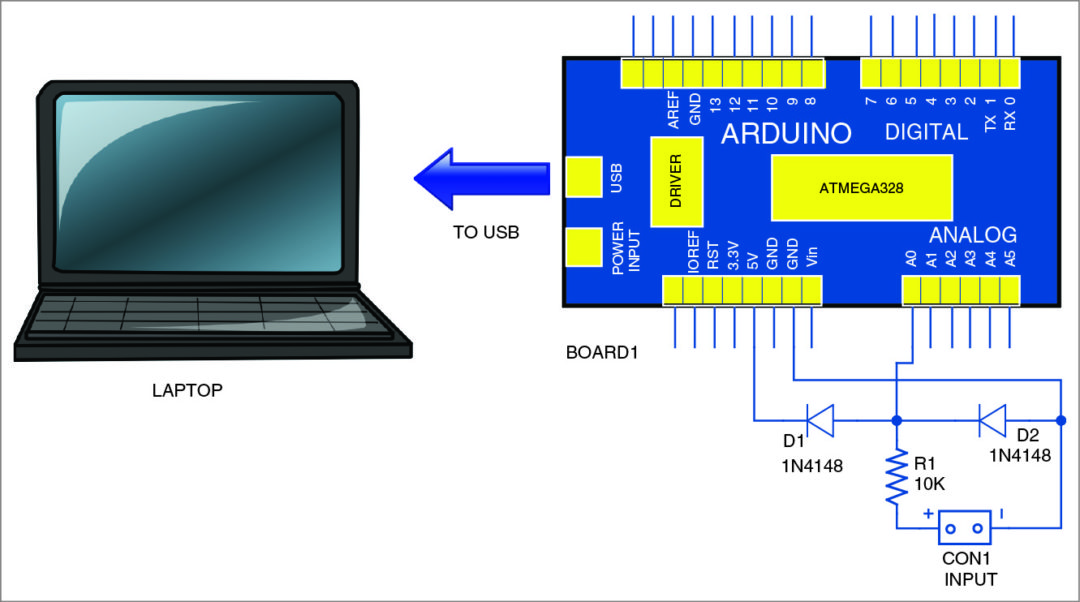

The LDC1312 element measures shifts in inductance because the knob rotates, changing these shifts into digital values that mirror the sensor’s inductance. These values are then retrieved by the MSP430F5528 microcontroller, which calculates the knob’s place primarily based on the sensor knowledge and updates the suitable output, resembling 7-segment shows. The LP5951 low-dropout (LDO) regulator performs a important function in powering the system by changing the 5V USB enter to a steady 3.3V output for the TIDA-00615 design. Compact in design, it ensures ample present output with a small SC70 footprint, superb for space-constrained purposes. Lastly, a 7-segment show driver interprets the binary-coded decimal output from the MSP430F5528, driving every show phase to precisely characterize the knob’s place.

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) format, and extra. The corporate’s web site has extra knowledge in regards to the reference design. To learn extra about this reference design, click on right here.