Key

Points of interest | The 200W DC/DC converter design presents excessive effectivity, low switching losses, and dependable isolation, that includes full digital management, decreased element wants, and complete monitoring for voltage, present, and temperature. | The 100W DC-DC converter presents an environment friendly 12V output with an LLC resonant circuit, reaching 88% effectivity, compact design, and enhanced efficiency by means of optimised MOSFETs and exact voltage regulation. | The 500W two-phase interleaved converter presents excessive effectivity, correct present sharing with out further {hardware}, and programmable section shedding, with fault protections to make sure secure and dependable operation. | The 250W high-voltage energy provide system presents over 96% effectivity, dependable efficiency throughout various masses, and key options like galvanic isolation, over present and over voltage safety, and versatile monitoring interfaces. | This 60kW reference design includes a 3-phase interleaved LLC topology for decreased enter present ripple and 98.5% peak effectivity, supporting versatile voltage configurations from 200V to 1000V with adaptable management. |

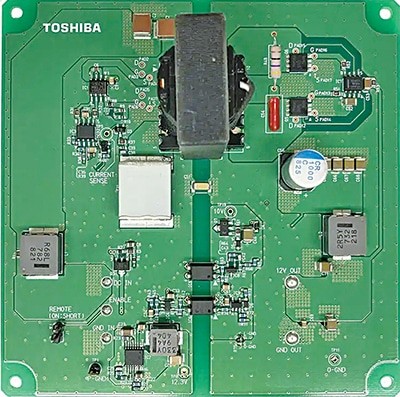

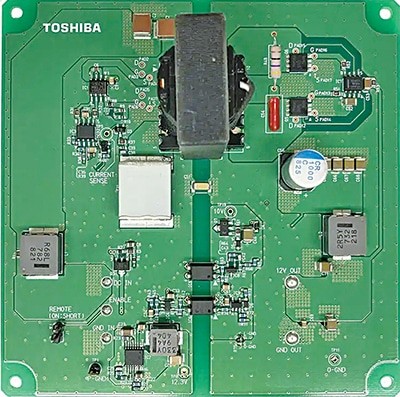

Highlights | The 200W DC/DC LLC resonant converter reference design by Microchip simplifies the design course of for energy conversion. Working over an enter vary of 350V dc-420V dc, with a nominal 400V enter, this design delivers a 12V DC output whereas guaranteeing voltage isolation between the first and secondary sides. Effectivity is achieved through zero voltage switching (ZVS) on the half-bridge converter and nil present switching (ZCS) on the synchronous rectifier, additional enhanced by utilizing a synchronous rectifier as a substitute of a full-wave rectifier. The design permits for switching strategies, resembling LLC, reaching as much as 95% effectivity and lowering switching losses. Options embrace low energy consumption at no load, programmable soft-start, and monitoring and safety for voltage, present, and temperature. The design incorporates a half-bridge topology, utilizing a resonant tank circuit with a capacitor, an inductor, and an isolating transformer. The transformer’s magnetising inductance eliminates the necessity for a second inductor, minimising converter measurement, value, and complexity, with a synchronous rectifier on the secondary aspect for effectivity. | The 100W LLC DC-DC converter reference design by Toshiba produces a 12V output utilizing an LLC resonant circuit that switches the high-side and low-side MOSFETs on the first aspect at a 50% responsibility cycle, adjusting frequency to manage output voltage. The ability provide achieves 88% effectivity at full load and has a 110mm x 110mm x 35mm footprint, excluding enter and output terminals. MOSFETs and a photocoupler improve efficiency and reliability, whereas the enter voltage is stepped down by the LM46000 converter to provide 12V to the LLC controller. Enter voltage vary is about by exterior resistors dividing the enter voltage to feed the allow pin of the DC-DC converter, which begins switching when this voltage exceeds 2.0V. The gate drive circuit design impacts effectivity and EMI, requiring a stability between the 2. Output voltage is set by exterior resistors and a shunt regulator, which adjusts the photocoupler present to match the reference voltage based mostly on the divided output voltage. | The TIDM-1001 reference design by Texas Devices is a 500W digitally managed, two-phase interleaved LLC resonant converter, that includes a C2000 microcontroller (MCU) to handle operational modes and generate PWM indicators for energy switches. Its present sharing mechanism ensures correct present stability between phases with out further {hardware}, enhancing effectivity and reliability. Delivering 500W—250W per section, with an enter vary of 370V to 410V DC and a 12V DC output, the design operates with a resonant frequency of 250kHz and a switching frequency vary of 200kHz to 350kHz. With a peak effectivity of 94.5% and effectivity maintained at partial masses, it additionally options programmable section shedding for load-based adjustment. Fault protections, together with section and output overcurrent and overvoltage protections, guarantee secure operation. The design makes use of C2000 powerSUITE instruments for improvement and customisation, supported by all of the elements, which allow energy density and dependable operation in energy techniques, making it appropriate for energy provide necessities. | The excessive voltage resonant converter board (HVP-LLC) from NXP Semiconductors, mixed with the HVP-KV46F150 controller card, types a 250W energy provide system with a 390V DC enter and a 12V/21A output. Utilising GaN switches and a digitally managed synchronous rectifier, it achieves effectivity over 96% throughout numerous masses. Working at excessive voltages, the board requires cautious dealing with and is really useful to be used in a laboratory atmosphere by people skilled in excessive voltage techniques. The drive to enhance energy density in switched mode energy provides (SMPS) results in increased switching frequencies, which usually improve switching losses in PWM converters and cut back effectivity. Though increased frequencies allow smaller passive elements, they usually require bigger warmth sinks or pressured cooling, main SMPS designers to discover resonant converter topologies to cut back losses. The LLC resonant topology, which features a transformer, gives further benefits, resembling galvanic isolation and voltage adjustment. Outfitted with cooling, digitally managed synchronous rectification, galvanic isolation, over present and over voltage safety, and interfaces for connectivity and monitoring, it accommodates a number of MCU playing cards and gives a load change for step-response tuning. | The CRD-60DD12N-Ok is a reference design from Wolfspeed. The design makes use of 1200V silicon carbide MOSFETs and 650V Schottky diodes to optimise efficiency. Its 3-phase interleaved LLC topology reduces enter present ripple and maximises effectivity, reaching 98.5% peak effectivity and an influence density of 4.83kW/L. The converter helps an output voltage vary of 200V to 1000V, with an adaptive management system working at switching frequencies from 120kHz to 250kHz. Enter voltage is managed from 650V to 900V through an active-front-end AC-DC converter, and the secondary aspect is configurable in collection or parallel, relying on output voltage wants. In parallel mode, the converter delivers output voltages from 200V to 500V DC at various currents, capped at 60kW, whereas in collection mode, it gives output from 500V to 1000V DC, additionally capped at 60kW. Working with air cooling and a CAN interface for PC-based management, this design presents a flexible and environment friendly place to begin for brand spanking new silicon carbide based mostly techniques. |