It operates with enter voltages starting from 7V to 18V, guaranteeing compatibility with automotive energy techniques and functions requiring 3-phase full-bridge topology.

A 150W coolant pump performs a vital position in varied industrial, automotive, and mechanical functions, guaranteeing environment friendly thermal administration by circulating coolant fluid to control temperature. In automotive techniques, these pumps preserve optimum engine temperatures, guaranteeing clean operation and gasoline effectivity. In industrial machines, they’re important for cooling processes in CNC machines, injection molding, and energy turbines. Such pumps discover functions in HVAC techniques, medical tools, and renewable vitality setups like photo voltaic thermal techniques, the place exact cooling management is important.

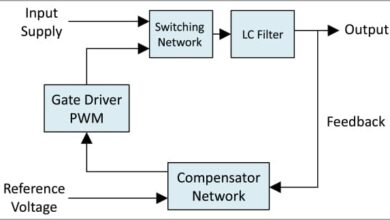

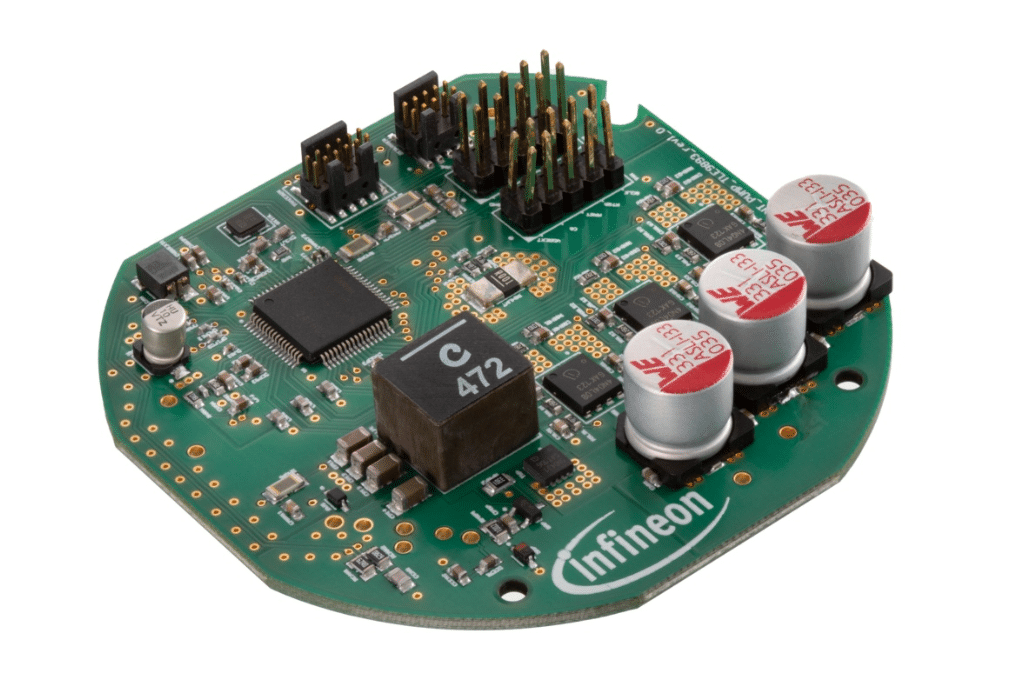

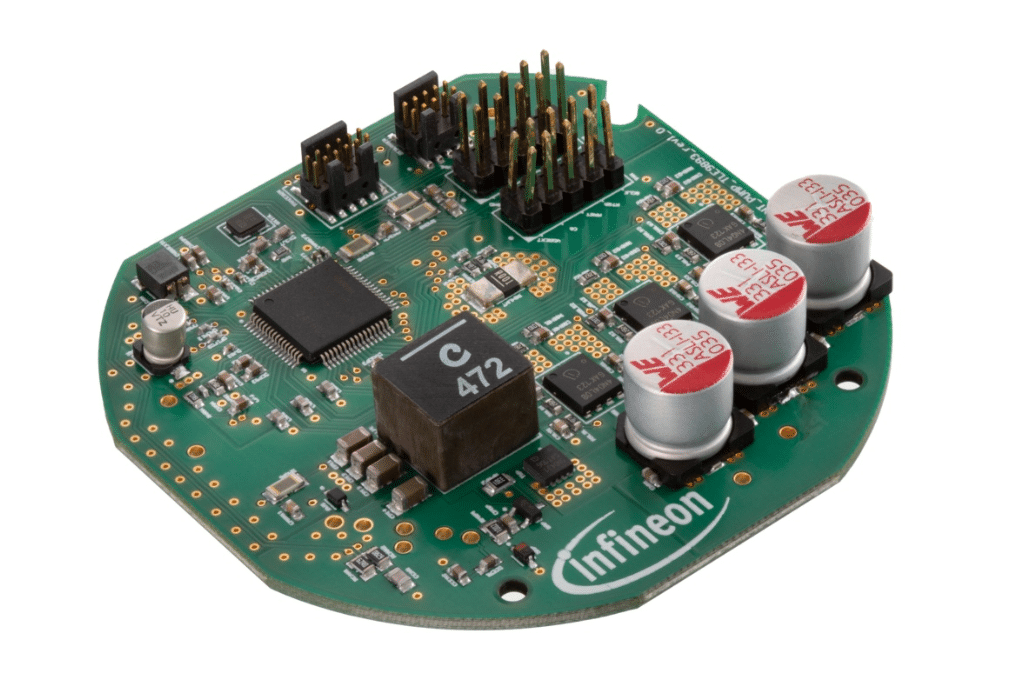

The 150W coolant pump reference design REF_COOLANTPUMP150W by Infineon Applied sciences AG is particularly tailor-made to drive 12V brushless DC (BLDC) motors, providing a nominal energy output of 150W. This design serves as a benchmark for optimizing electromagnetic compatibility (EMC), part choice, and thermal efficiency, guaranteeing environment friendly and dependable operation. It supplies a clean place to begin for prototyping, that includes quite a lot of connectors to simplify the method. The reference design incorporates superior Infineon elements, together with MOSFETs and the MOTIX™ MCU with CAN-FD, to boost efficiency and communication.

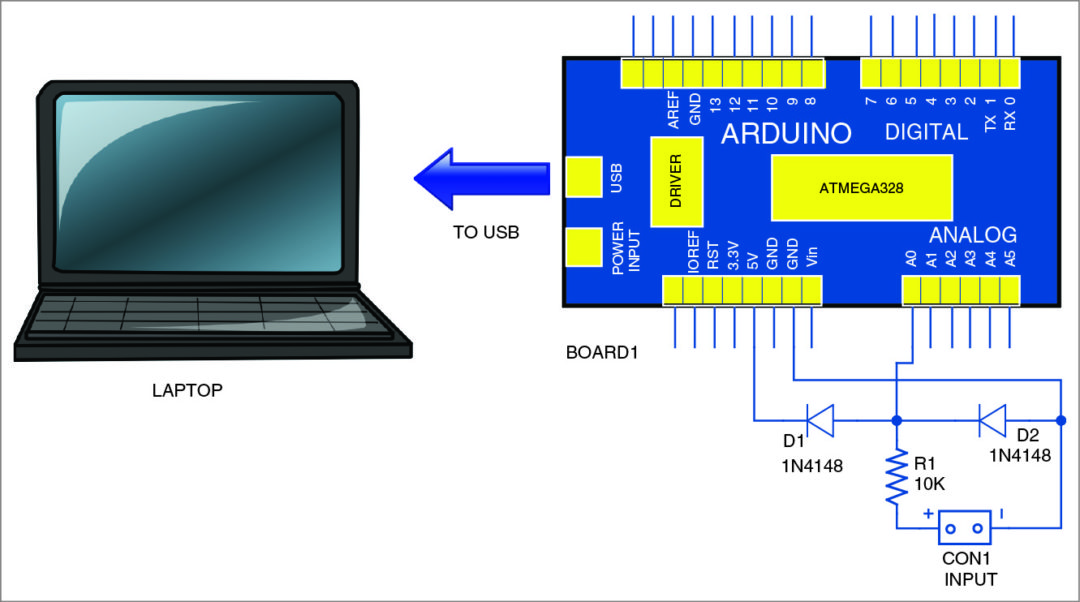

On the core of this answer is the TLE9893-2QKW62S, a part of the MOTIX MCU household, a 32-bit System-on-Chip (SoC) motor driver that integrates a 3-phase BLDC motor driver and an Arm Cortex-M3 core for superior motor management algorithms. It contains an built-in CAN-FD transceiver for high-speed communication and versatile general-purpose I/O choices. Complementing that is the IAUCN04S7N019D, a Twin MOSFET primarily based on OptiMOS 7 know-how, optimized for motor drive and automotive functions. Its compact 5mm x 7mm Twin SSO8 package deal minimizes PCB area, whereas providing RDS(ON) values from 1.8 mΩ to five.6 mΩ, enhancing general effectivity.

This reference design helps as much as 150W energy output, guaranteeing optimum efficiency for 12V automotive coolant pumps. The board design is extremely optimized, with a compact diameter of 60mm, and integrates superior thermal administration to boost reliability. It incorporates a high-temperature FR4 PCB with 1oz copper unfold throughout 4 layers, enabling environment friendly warmth dissipation. The one-sided part mounting and varied connectors, together with these for CAN, monitoring, and exterior sensors, facilitate ease of use and debugging via SWD and tracebox ports.

Its minimal invoice of supplies (BOM) and decreased PCB measurement consequence from the usage of extremely built-in elements just like the MOTIX MCU and the compact OptiMOS-7 Twin MOSFET. The design gives scalability, supporting energy outputs from 100W to 1000W by leveraging the MOTIX MCU platform. This makes it appropriate for varied 3-phase motor drive functions, specializing in automotive coolant pumps and 12V BLDC motor options.

Infineon Applied sciences has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) format, and extra. The corporate’s web site has extra knowledge in regards to the reference design. To learn extra about this reference design, click on right here.