The design maximizes effectivity with a scalable battery charger design. It helps varied panels, chemistries, and energy ranges for outside purposes.

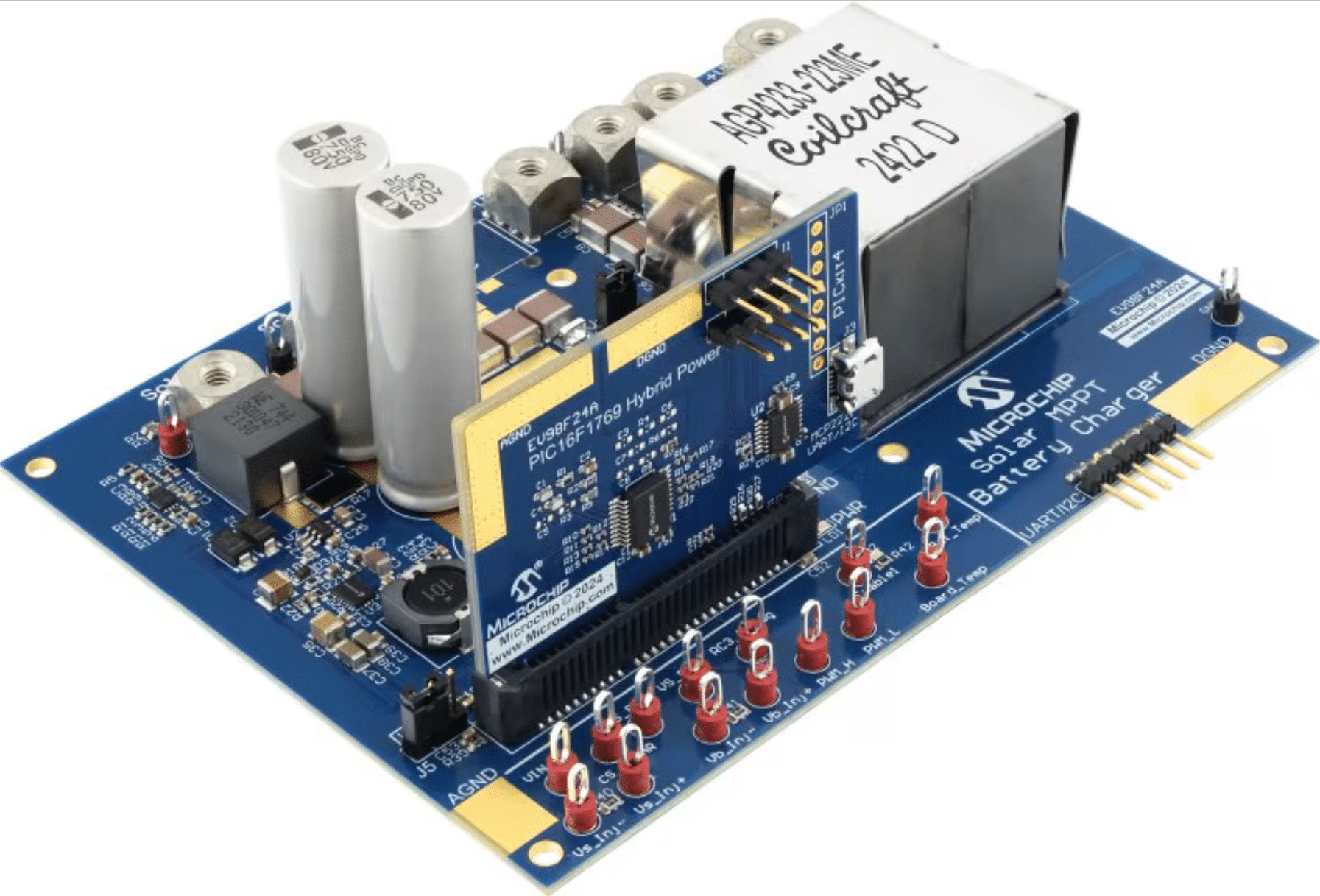

Photo voltaic Most Energy Level Monitoring (MPPT) battery charger reference design from Microchip is optimized to extract probably the most energy from photo voltaic panels in several lighting circumstances, shading, temperature modifications, and solar angles. It ensures protected battery charging with predefined profiles and works with varied battery chemistries and photo voltaic panel sorts. This makes it appropriate for powering streetlights, street indicators, moveable turbines, cooling followers, and client electronics in RVs.

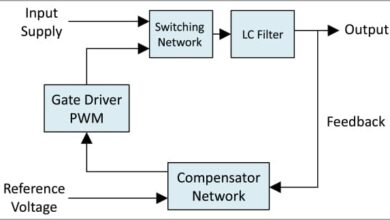

Engineers can shortly use this open platform to develop a photo voltaic charger utilizing synchronous buck topology. The design helps an influence vary of lower than 20W to over 400W, making it extremely scalable. The PCB is designed with elective footprints for enter/output capacitors, sync-buck MOSFETs, and inductors, permitting engineers to customise their setup. Further options, comparable to battery and output load present/voltage/energy metering (for gas gauging), temperature monitoring, and automated cooling fan management, could be added or eliminated primarily based on the precise necessities of the top product.

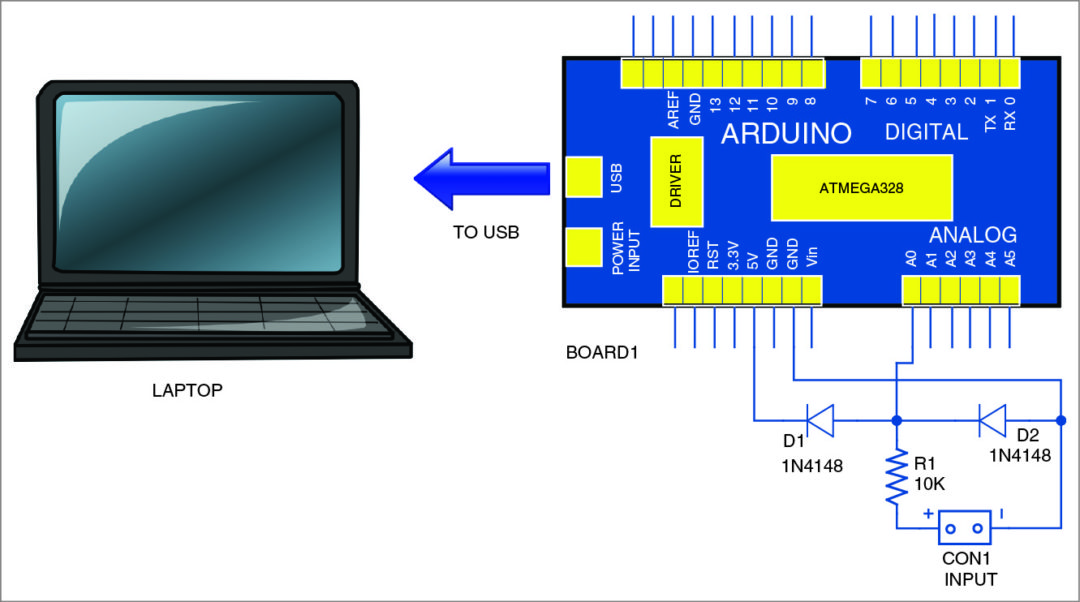

The included firmware gives an open improvement platform, simplifying the mixing of charging algorithms, security options, I2C interfaces, and power-point monitoring algorithms. These features are applied as state machines, referred to as from a easy primary loop, and could be up to date or changed as required. The {hardware} is totally abstracted from the state machines, enabling simple configuration and customization. A Home windows-based GUI permits full management and configuration of the board through a single USB connection, with reside updates of all parameters proven numerically and graphically all through the cost cycle.

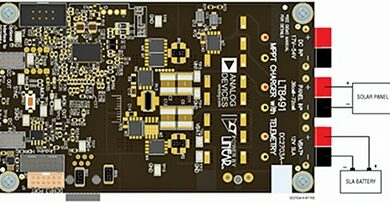

The design gives a number of advantages, together with compatibility with photo voltaic panels with output voltages starting from 15 to 60 V. It gives flexibility in delivering output energy between 10 and 400 W and may hook up with both a single photo voltaic panel or sequence and parallel linked arrays. MPPT ensures probably the most environment friendly working level for the photo voltaic panel. Moreover, it helps cost profiles for a number of battery chemistries, additional enhancing its versatility.

The CSM controls the system by shifting by way of totally different steps to cost the battery safely. There are separate state machines for every kind of battery, which could be turned on utilizing settings. Every step controls the {hardware} to make sure the correct quantity of present and voltage is given to the battery, then strikes on to the subsequent step. Every kind of {hardware} might have modifications to those features to work accurately.

The MPPT Photo voltaic Charger analysis board is pre-calibrated for the best voltage and present ranges for every board. If the photo voltaic enter vary or battery setup modifications, you may alter the voltage dividers and present monitoring resistors to make use of the controller’s ADC vary totally. In manufacturing, every board must be calibrated utilizing a precision voltage and present supply that matches the ultimate product’s enter and output voltage vary.

Microchip has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has further information in regards to the reference design. To learn extra about this reference design, click on right here.