The design reveals wearable coronary heart fee monitoring with a single 8-bit microcontroller, utilizing Section Division Multiplexing to measure indicators with out interference and scale back prices.

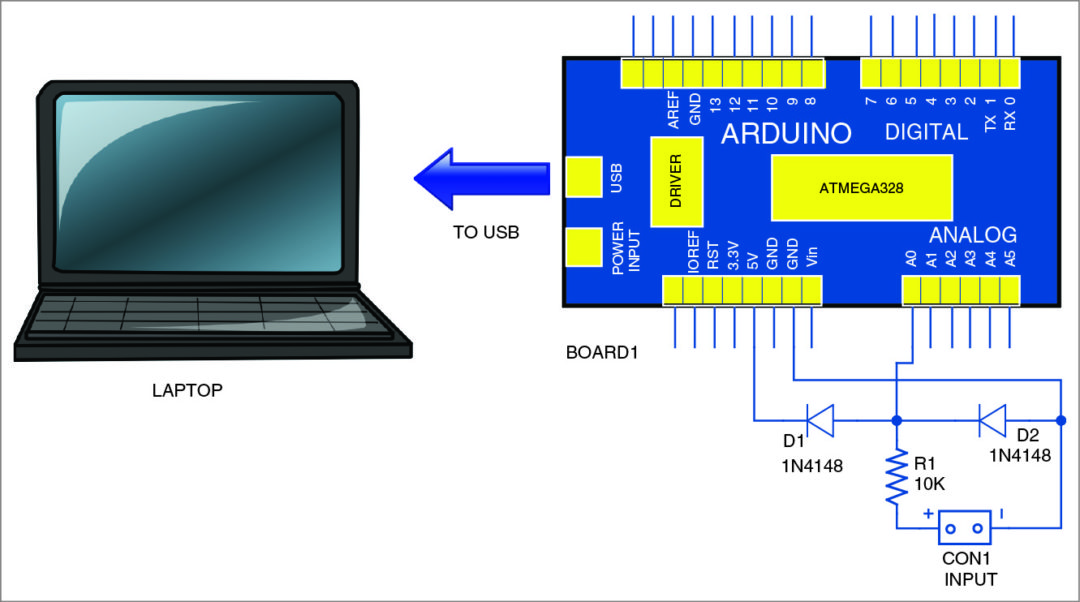

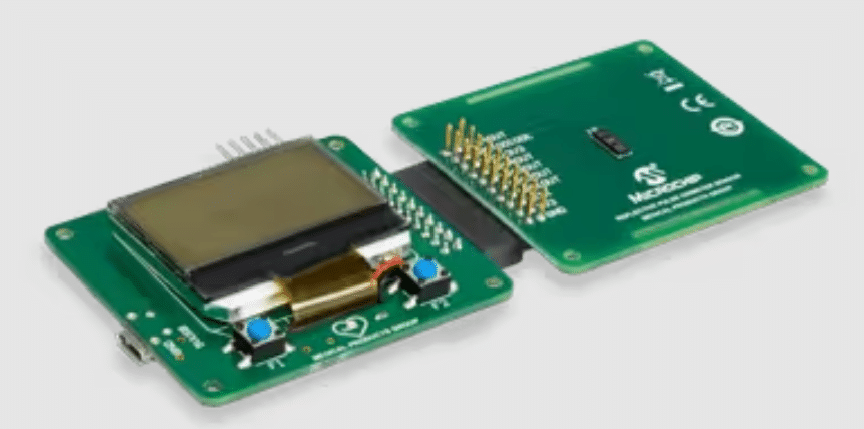

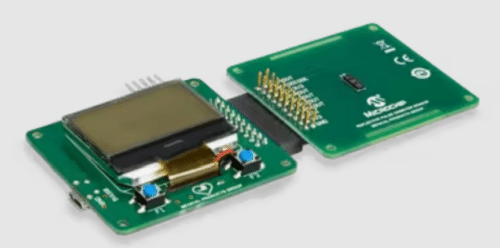

Designing wearable medical gadgets as we speak includes combining coronary heart fee monitoring with different well being and compliance monitoring. Most wearables measure coronary heart fee with reflective screens. These screens typically wrestle with noise regardless of utilizing superior and expensive circuits like Analog Entrance Finish (AFE) chips. Discovering a less expensive approach to scale back this noise is essential. The demonstration board for wearable coronary heart fee monitoring from Microchip illustrates how one can precisely measure coronary heart fee utilizing only a single 8-bit microcontroller (MCU). It makes use of a Section Division Multiplexing approach to measure varied indicators directly with out interference. This methodology makes use of the PIC16F1779 MCU’s built-in Core Impartial Peripherals (CIPs), permitting for a low-noise design and chopping down on prices in comparison with conventional strategies.

The design highlights the capabilities of utilizing a single-chip setup to measure coronary heart fee successfully. It makes use of the eXtreme Low Energy 8-bit microcontroller (MCU), which includes a number of built-in options. One key characteristic is the Section Division Multiplexing approach that permits for the simultaneous measurement of a number of indicators with none sign interference, referred to as cross speak. This integration considerably lowers the general invoice of supplies (BOM) price because of using Core Impartial Peripherals (CIPs) and built-in analog functionalities.

The CIPs additionally assist in lowering software program overhead, enhancing the system’s effectivity. The MCU contains built-in 10-bit Digital-to-Analog Converters (DACs) and operational amplifiers (op amps) that exactly management the LED depth, essential for correct coronary heart fee detection. Moreover, Configurable Logic Cell (CLC) CIPs are employed to handle the LED driving immediately, thus eliminating the necessity for CPU involvement on this course of. This setup not solely simplifies the design but in addition enhances efficiency whereas retaining prices low.

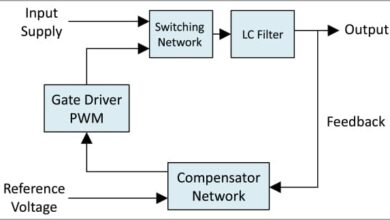

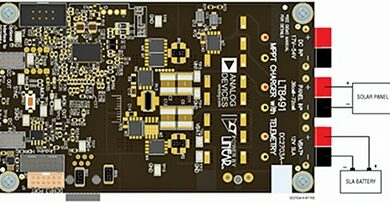

The MCU used is very built-in, that includes each Clever Analog and digital parts suited to quite a lot of purposes together with lighting, energy provides, battery charging, motor management, and different basic functions. These gadgets are geared up with a number of operational amplifiers, 5-/10-bit DACs, high-speed comparators, a 10-bit analog-to-digital converter (ADC), 10-/16-bit pulse-width modulators (PWMs), and a Programmable Ramp Generator (PRG). Additionally they embody different peripherals that allow the creation of closed-loop programs internally with no need exterior pins or extra PCB house.

The MCU can drive subtle features like an LED dimming engine utilizing the ten and 16-bit PWMs, Digital Sign Modulator (DSM), and tri-state output operational amplifiers. The Peripheral Pin Choose (PPS) characteristic provides flexibility, simplifying the PCB structure and enhancing peripheral utilization by permitting customers to remap digital peripheral pins to any enter/output pin. This versatility makes these microcontrollers perfect for effectively dealing with complicated duties throughout a number of purposes.

Microchip has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has extra information concerning the reference design. To learn extra about this reference design, click on right here.