The facility of ultrasonic circulation measurement is inside attain. Harness time-of-flight know-how to create low-power options for liquid and fuel circulation methods.

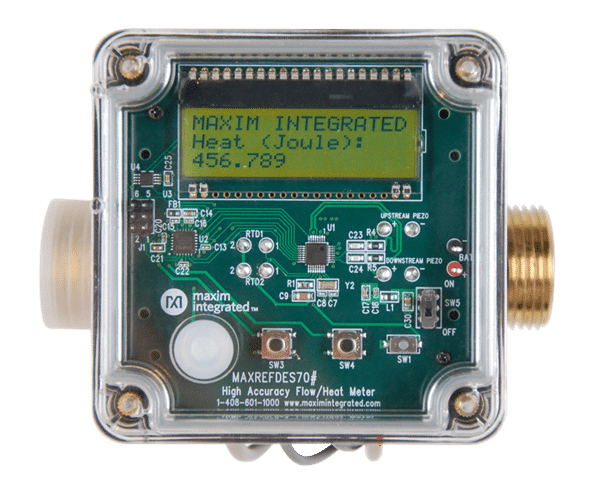

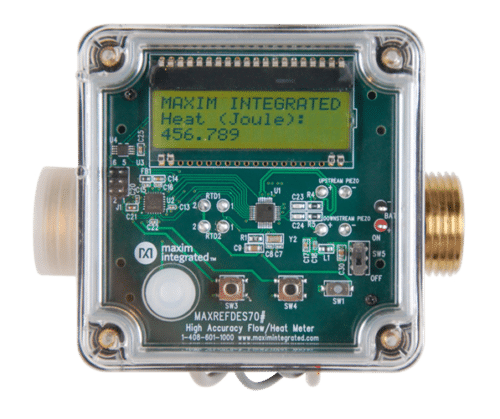

Ultrasonic circulation meters are remodeling the measurement of liquid and fuel flows. These meters are important for income assortment, leak detection, and the conservation of pure sources, making them central to utility and industrial methods for water, fuel, and warmth distribution. Mechanical circulation meters, which use transferring elements to measure fluid velocity, are the commonest kind. The MAXREFDES70 ultrasonic time-of-flight (TOF) circulation meter by Maxim Built-in makes use of piezoelectric transducers to ship and obtain ultrasound waves each upstream and downstream inside a pipe. The circulation price will be decided by measuring the distinction within the TOF between the 2 instructions and making use of digital sign processing strategies.

Utilizing this reference design, design engineers can develop ultrasonic circulation meters that measure liquid and fuel circulation for purposes corresponding to utility methods for water, fuel, and warmth distribution. This design permits engineers to maneuver past mechanical circulation meters, utilizing piezoelectric transducers to measure TOF variations between waves travelling upstream and downstream in a pipe to calculate the circulation price.

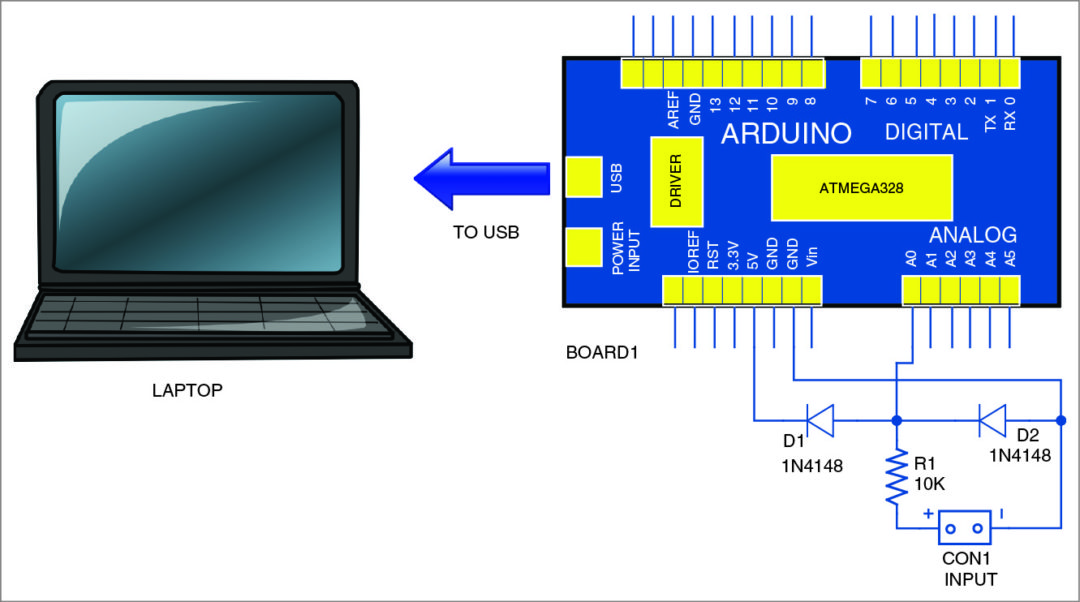

On the system’s core is the MAX35101, which integrates capabilities for automated TOF measurements, together with ultrasound pulse technology, detection, TOF calculation, temperature measurement, and a real-time clock (RTC). The time-to-digital converter operates in varied automated occasion timing modes, requiring minimal interplay from the host microcontroller, decreasing general energy consumption.

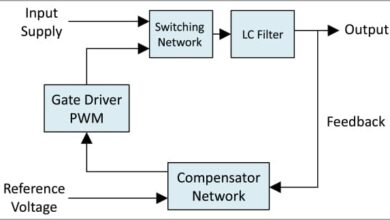

The system operates on the TOF measurement precept. It options two piezoelectric transducers that operate as transmitters and receivers for ultrasound waves. The meter alternately transmits and receives ultrasound pulses between the transducers, with pulses travelling downstream and upstream. Ultrasound pulses journey sooner downstream than upstream, and the TOF distinction between these two instructions is proportional to circulation velocity. A bigger TOF distinction signifies sooner fluid circulation. When fluid circulation stops, the TOF distinction turns into zero. The MAX35101’s digital processing, analogue front-end circuits, and calculation algorithms make sure that TOF measurements are dependable.

The gadget simplifies circulation computation with automated differential TOF measurement. Early edge detection ensures constant wave patterns and reduces errors. A built-in arithmetic logic unit calculates TOF variations, whereas a programmable receiver hit accumulator minimises the necessity for host microprocessor intervention.

The system is managed by the EFM32ZG110, a 32-bit ARM Cortex-M0+ microcontroller working at 14 MHz with 32 KB of inside flash. The microcontroller communicates with the time-to-digital converter and an LCD module by way of SPI and GPIO pins. The MAX4721 is a low-voltage, low-on-resistance analogue change used to isolate the LCD module’s SPI interface when the LCD is powered off, decreasing present leakage to five nA and conserving battery life.

Maxim Built-in has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) format, and extra. The corporate’s web site has further knowledge in regards to the reference design. To learn extra about this reference design, click on right here.